To maintain your belt-driven equipment, you need to ensure that the belts are not too tight or too loose. Either condition can reduce the lifetime of the belt, reduce the machine's operating efficiency, and lead to excessive down-time for belt replacement.

The TRUMMETER optical precision instrument accurately measures belt tension (a.k.a. strand force) without removing the belt from the machine or deforming the belt. The belt color or makeup does not affect the measurements. The TRUMMETER can even be used with ribbed and toothed belts. �Steel strands in the belt are not necessary for taking accurate measurements.

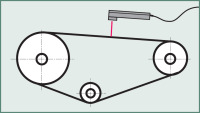

The TRUMMETER measures the belt tension and strand force by measuring the belt's natural vibration frequency. This, in combination with linear belt mass and the length of unsupported belt are plugged into a mathematical formula that produces the belt tension. The calculations are performed in the instrument so that you do not need to worry about transcription or calculation errors.

| Measuring range: | 10-800 Hz |

| Digital sampling error: | < 1% |

| Indication error: | ±1 Hz |

| Total error: | < 5% |

| Nominal temperature: | +20C |

| Operationg temperature: | +10C to +50C |

| Shipping temperature: | −5C to +70C |

| Casing: | ABS Plastic |

| Languages: | English, French, German, and Italian |

| Free strand length: | up to 9.99 m |

| Belt mass: | up to 9.999 kg/m |

| Power supply: | 9V battery |

The TRUMMETER comes with a hard plastic protective case, measuring probe, and 9V battery.

If the belt is very heavy or if the unsupported length is very long, it may vibrate at a frequency lower than 10 Hz. In such a case, test using a shorter length of belt. Further information can be found in the reference manual.

Technical Reference Manual: TR-2011-engl.pdf (430 kB)